Pre-Engineered Flammable Lockers

At U.S. Chemical Storage we strive to give you the best solution for your operations. This building and its accompanying accessories can be engineered to meet the following approvals and certifications based upon your unique set of needs.

Reduce the risk of fines by managing your chemical drum storage needs with pre-engineered, non fire-rated outdoor storage lockers from U.S. Chemical Storage. All rugged, pre-engineered, non fire-rated lockers are manufactured from heavy gauge steel to withstand a variety of outdoor environments and inclement weather.

VIEW

Pre-engineered, non-combustible turf chemical lockers promote safe handling and storage practices of agricultural management chemicals. Use these rugged, non-fire-rated lockers to house your chemical pesticides, fertilizers, and more, safely and securely.

VIEW

Flammable storage paint lockers are designed to storage flammable and combustible materials safely and compliantly. Meets EPA, OSHA, & NFPA regulations.

READ MORE

Storing bulk chemicals can lead to a disaster if improper chemical storage buildings are used. Not every building is safe for chemical storage.

READ MOREChemical storage buildings manufactured by U.S. Chemical Storage are designed to get your operation compliant. Contact one of our technical sales engineers to learn how we can find the best solution for your compliance needs. You will also want to learn more about specific chemical storage requirements in your specific area by contacting your local “Authority Having Jurisdiction” (AHJ) who could be a local fire marshal, a municipal code official, or a city environmental department.

First consult the Safety Data Sheet (SDS) to determine the type of chemical you’re storing and any storage requirements listed. There are two main classifications of buildings to consider: fire-rated and non-fire-rated steel buildings. There are three main questions you should answer before engineering or design can begin on your building: what is to be stored, how much of it is being stored, and where is the location it will be stored? You will also need to consult with your local “Authority Having Jurisdiction” (AHJ) or local code expert to determine your area’s specific storage building requirements. Our team at U.S. Chemical Storage has a wealth of knowledge, experience, and resources to help analyze your storage needs, but the final approval is made by the local AHJ, so you will need to ultimately ask them about your requirements early in the planning process.

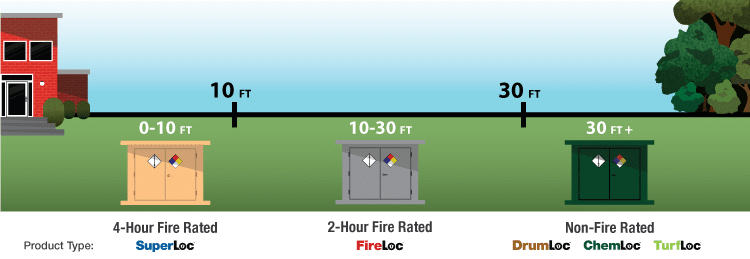

Location of the building can be either inside another building or outside to fit your needs. Fire Separation, which is the amount of fire rating required between two occupancies, or the separation distance between those two occupancies, is determined by the type of chemical or hazard being stored, and distances between buildings, egress pathways, or environmental features. To determine the required fire separation, it is best to consult with your local code authority. Inside another building or within 10 feet of another building, you’ll be required to have a 4-hour fire rating. If your hazmat storage building is located at distances 30 feet or greater your building may not be required to have a fire rating at all.