What You Need to Know About Flammable Paint Storage Buildings

Go Directly To Section:

- Flammability of Paint

- Required Fire-Ratings

- Climate Control

- Racking and Shelving Systems

- Explosion Relief Panels

- Fire Protection Features

- Storing Other Chemicals

- Standard Sizes

Flammability of Paint

Most paints are either oil-based or water-based. Because they contain a high level of solvents, oil-based paints are considered flammable per OSHA. But, it’s important to point out that some water-based paints may also be dangerous. Manufacturers supply Safety Data Sheets (SDS) for all chemicals they sell, including paints. The SDS relays important information for safe usage in different sections of the document. Section 2 describes its hazards, including its classification. In Section 7, guidance for safe handling and storage is provided. And in Section 9, details of the physical and chemical properties of the material are given. Read each of these sections carefully when deciding how to store your paint materials.Required Fire-Ratings for Paint Storage and Mixing

A fire-rating refers to a type of building construction that is resistant to fire for a certain amount of time. These buildings allow more time to evacuate the area in case of a fire. What’s more, the fire rating can afford emergency personnel more time to extinguish a fire before it spreads.When storing chemicals – including paint – the required fire-rating is dependent on the following:

- The flammability or hazard classification of the product(s) – from the SDS as discussed above

- Distance or setback from other buildings/occupancies

- The occupancy of the building as defined in Chapters 2 and 3 of the International Building Code (IBC)

- The number of materials being stored as related to IBC Table 307.1(2)

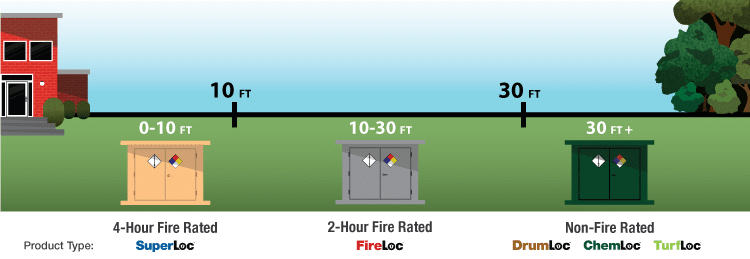

Recommended Building Distances

Recommended Building Distances

Note: Always check with the local Authority Having Jurisdiction (AHJ) for clarity about local requirements for flammable paint storage.

Climate Control for Flammable Paint Storage Buildings

The temperature of paint in storage is important. Controlling it protects both its quality and its performance consistency. Flammable paint storage buildings are sometimes directly connected to spray booths. Maintaining paint viscosity is critical for ensuring a consistent quality finish. Temperature fluctuations affect paint viscosity and the quality of the finished paint job. The paint itself is also affected by temperature extremes. Overheating paint destroys some of the chemical properties and can render it useless. Freezing paint separates it into its constituent parts. Both of these fluctuations create a risk of inadequate mixing during use. U.S. Chemical Storage supplies climate control options for paint storage buildings. These include heaters, chillers, HVAC units, or a combination of any of them. Automatic temperature controllers help maintain temperature differentials regardless of internal or external conditions. Sensors and alarms also notify operators of temperature variations from the set point.Explosion Relief Panels for Paint Storage Buildings

Regulations require flammable paint storage buildings to have explosion relief panels in certain conditions. For instance, mixing paint generates flammable vapors. These vapors then have the potential to cause an explosion when ignited. Explosion relief panels create a path, directing the force of an explosion away from personnel. They help minimize the risk of injury. In addition, IBC Table 414.5.1 requirements specify NFPA 69 or explosion relief panels be used when storing and dispensing Class 1A materials as well as dispensing Class 1B materials.Fire Protection Features When Storing Paint

There are two main fire protection features of flammable paint storage buildings – fire suppression and mechanical ventilation. Fire suppression systems automatically discharge dry chemical or water as an extinguishing agent in case of fire. The purpose is to put out a fire as soon as it is detected, thus limiting its damage. Alarms notify operators upon activation. Peripheral equipment like heaters, HVAC units, and ventilation systems all shut down automatically when dry chemical suppression is used. Mechanical ventilation uses a fan to remove air from the flammable paint storage building and replace it with fresh air. This prevents flammable vapors from accumulating to create an explosive atmosphere.Storing Other Chemicals in a Paint Storage Building

Flammable paint storage buildings are custom-designed and built for your application. Many companies have more than one type of chemical or container stored in each building. Some companies keep flammable paint waste in their storage buildings too, while waiting for safe disposal at an approved site. Just remember to heed basic safe chemical storage precautions. Avoid storing incompatible materials near each other. A release of one may cause the other to ignite. For example, oxidizers release oxygen and may accelerate a fire.Standard Sizes of Paint Storage Buildings

U.S. Chemical Storage manufactures custom paint storage buildings to the customer’s size requirements. Regulations allow chemical storage buildings of up to 1,500 square feet. Modular buildings may be used when a larger footprint is necessary. A wide variety of racking and shelving options are also available for paint storage buildings for safe and efficient material handling. These include multi-tier gravity sliding pallet racks, cylinder racks, and drum racks. Shelves are available for smaller containers.Contact U.S. Chemical Storage for Flammable Paint Storage Buildings

U.S Chemical Storage has extensive experience in bulk paint storage applications. Our experts help you design the best solution for your needs depending on regulations, site layout, and intended use of the facility.References

- OSHA. Hazard Communication Standard: Safety Data Sheets

- Grainger. Outdoor Chemical Storage Buildings

- Times-News – Twin Falls, ID. Paint Explosion Causes Fire in Heyburn Business

- Codes Safe.org – International Building Codes 2018