The Real Cost of a Chemical Fire Isn’t The Fire—It’s the Shutdown

The Real Cost of a Chemical Fire Isn't the Fire - It's the Shutdown

When companies think about the cost of a chemical fire (aside from any human injuries or loss, of course), they often focus on damaged inventory, destroyed property, and cleanup expenses. But in most real-world incidents, those costs are only a fraction of the real impact: the shutdown.

The most expensive part of a chemical fire rarely happens during the fire itself. It happens in the days, weeks, and months that follow—when production stops, investigations begin, and entire operations grind to a halt.

Even relatively small chemical fires immediately cause:

- ⦾ Mandatory shutdowns while fire departments and authorities investigate

- ⦾ Environmental and safety inspections before re-entry is allowed

- ⦾ Insurance inspections and documentation requirements

- ⦾ Equipment testing, air quality assessments, and structural evaluations

- ⦾ PR and media activities

- ⦾ Delayed or canceled production schedules

- ⦾ Communication with customers

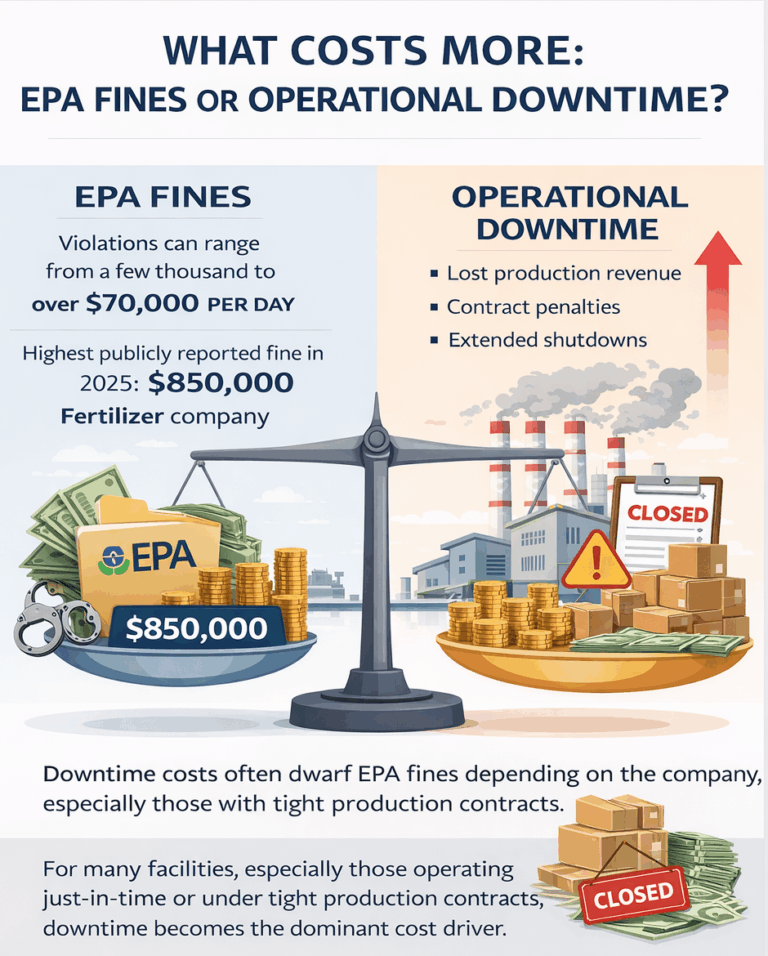

EPA fines for environmental and chemical safety violations can range from a few thousand dollars a day to over $70,000 per day. The largest publicly report fine for 2025 was for a fertilizer company for $850,000 with a variety of violations.

The cost of operational downtime, disruptions, and shutdowns can often dwarf those fines depending on the company. For many facilities, especially those operating just-in-time or under tight production contracts, downtime becomes the dominant cost driver.

Downtime Costs v. Fines

Lost production revenue, idle labor, missed delivery commitments, and contractual penalties can eclipse the value of the chemicals involved within days.

In regulated industries like pharmaceuticals, food & beverage, and advanced manufacturing, restarts aren’t immediate. Validation, requalification, and safety approvals often extend shutdowns well beyond the initial incident.

For industries that monopolize the market, like many in medical supplies, for example, the effects are far reaching along the entire supply chain. At that point, you’re not just affecting your business or your customers, it’s affecting an entire economic ecosystem.

At that point, the question is no longer “What did the fire damage?” but “How long can we afford to be offline?”

Convenience Over Containment?

In many post-incident reviews, the root cause is not a lack of safety awareness—but a storage strategy that prioritized convenience over containment.

Common issues include:

- ⦾ Flammable or reactive chemicals stored inside occupied buildings without adequate fire rated construction

- ⦾ Inadequate fire separation between hazards and production areas

- ⦾ Ventilation systems that spread smoke or heat instead of containing it

- ⦾ Storage solutions designed to meet code minimums, not worst-case scenarios

When chemicals are stored within the production footprint, even a small event can force a full facility shutdown if the proper prevention measures aren’t taken.

FURTHER READING: Insurance in the Chemical Industry

Containment changes the outcome

Facilities that isolate chemical hazards—using dedicated, fire-rated storage structures—often experience very different outcomes should an event occur.

When a fire is contained:

- ⦾ Investigations are more limited in scope

- ⦾ Production areas may remain unaffected

- ⦾ Cleanup and restart timelines are shorter

- ⦾ Insurance or regulatory scrutiny time is reduced

Having the proper documentation of the measures you’ve taken prior will prove invaluable to all the parties involved. That preparation is not just compliance—it’s operational resilience.

FURTHER READING: 8 Must Haves When Purchasing a Chemical Storage Building

Chemical storage is a business decision

Chemical storage is often treated as a safety or compliance issue alone. In reality, it’s a valuable, core part of the business that can not be ignored.

Facilities that plan for maximum containment practice rather than minimum compliance reaction are better positioned to:

- ⦾ Protect uptime

- ⦾ Reduce financial exposure

- ⦾ Maintain customer trust with key accounts

- ⦾ Manage insurance underwriting costs

- ⦾ Resume operations faster should an incident occur

The real question is not whether a facility can pass an inspection—but whether it can keep running when something goes wrong.

Preventing chemical fires is critical. But containing them—so they don’t shut down your operation—is what protects your business. Reach out to the team at U.S. Chemical Storage today and we can help you mitigate your risk and engineer a custom solution for your set of unique risks. Call Today 1-800-233-1480 or fill out the form on the right side of this page.

References:

EPA – Civil Enforcement Program (fines, enforcement authority)

https://www.epa.gov/enforcement/fact-sheet-epas-civil-enforcement-programNFPA – Fires in Industrial or Manufacturing Properties (fire data & loss context)

https://www.nfpa.org/education-and-research/research/nfpa-research/fire-statistical-reports/fires-in-us-industrial-or-manufacturing-propertiesU.S. Chemical Safety Board – Chemical Incident Investigations (shutdowns & aftermath)

https://www.csb.gov/investigations/