Ready-to-Ship & Rental Chemical Storage Buildings

When time is of the essence, you can’t always wait for a custom solution to your chemical storage needs. U.S. Chemical Storage has ready-to-ship chemical storage buildings ready right now. Bring your operations into compliance with our pre-engineered ready-to-ship storage buildings easily and quickly.

To inquire about availability and pricing, email a U.S. Chemical Storage project specialist by filling out the form HERE , or call 800.233.1480 today.

Note: All of the below ready-to-ship chemical storage buildings are also available for rental. To learn more about rentals visit our rental buildings page.

Available NOW - for Purchase or Rental

Browse our current ready-to-ship inventory below. For more information on buildings, accessories, freight cost, and to purchase or rent, contact U.S. Chemical Storage at 800.233.1480.

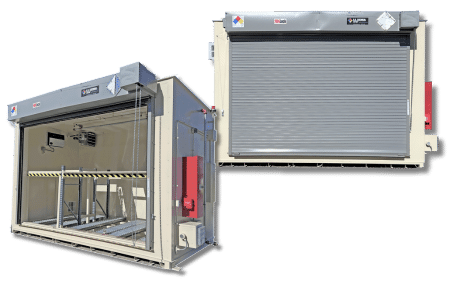

FL1709 'B' 2-hour fire-rated

*Freight not included

- 20′ long x 12′ deep x 12’4″ tall

- One currently available

- Class 1 Div 1

- Manual roll-up door 14′ wide

- Liquid Level Detector with strobe

- Dry Chem Fire Suppression with alarm

- C1-D1 Fan Forced Heater

- C1-D1 Air Conditioning Unit

- Sprinkler 2-Nozzle with FD hose connection

- 489 gal capacity containment sump

- Gravity rollers for 10 pallets

- Stationary rack for one pallet/tote

FL1709 'C' 2-hour fire-rated

*Freight not included

- 20’ long x 12’ deep x 11’10.5″ tall

- One currently available

- Class 1 Div 1

- Manual roll-up door 14′ wide

- Liquid Level Detector with strobe

- Dry Chem Fire Suppression with alarm

- C1-D1 Fan Forced Heater

- C1-D1 Air Conditioning Unit

- Sprinkler 2-Nozzle with FD hose connection

- 489 gal capacity containment sump

- Gravity rollers for 10 pallets

- Stationary rack for one pallet/tote

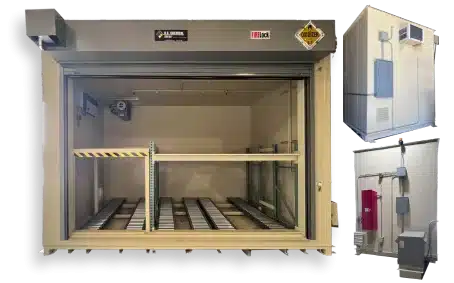

FL1709 'D' 2-hour fire-rated

*Freight not included

- 20’ long x 12’ deep x 11’10.5″ tall

- One currently available

- Class 1 Div 1

- Manual roll-up door 14′ wide

- Liquid Level Detector with strobe

- Dry Chem Fire Suppression with alarm

- C1-D1 HVAC unit

- Sprinkler 2-Nozzle with FD hose connection

- 489 gal capacity containment sump

- Gravity rollers for 12 pallets

FL1709 ‘E’ 2-hour fire-rated

*Freight not included

- 20’ long x 12’ deep x 12’4″ tall

- One currently available

- Class 1 Div 1

- Manual roll-up door 14′ wide

- Liquid level detector with strobe

- Dry-chem fire suppression with alarm

- C1-D1&2 fan-forced heater

- C1-D1 air conditioning unit

- Sprinkler 2-Nozzle with Fire Dept hose connection

- 489-gal capacity containment sump

- Gravity rollers for 11 pallets (5 above, 6 below)

- Stationary rack for one pallet/tote below

FL1709 ‘F’ 2-hour fire-rated

*Freight not included

- Approx 22’ long x 12’ deep x 12″ tall

- One currently available

- Class 1 Div 1

- Manual fire-rated roll-up door 14′ wide

- Liquid level detector with horn/strobe

- Dry-chem fire suppression with alarm

- C1-D1 fan-forced heater

- C1-D2 air conditioning unit

- 489-gal capacity containment sump

- 480/3P-208/3P General Purpose Transformer

- Gravity rollers for 10 pallets (4 above, 6 below)

- Stationary rack for one pallet/tote

Compliance & Approvals

At U.S. Chemical Storage we strive to give you the best solution for your operations. This building and its accompanying accessories can be engineered to meet the following approvals and certifications based upon your unique set of needs.

Frequently Asked Questions

Chemical storage buildings manufactured by U.S. Chemical Storage are designed to get your operation compliant. Contact one of our technical sales engineers to learn how we can find the best solution for your compliance needs. You will also want to learn more about specific chemical storage requirements in your specific area by contacting your local “Authority Having Jurisdiction” (AHJ) who could be a local fire marshal, a municipal code official, or a city environmental department.

Building size is determined by the amount of hazardous material you are planning to store, the need for occupancy or inspection around these materials, and must take into consideration the most efficient way of moving these materials into and out of your chemical storage building.

Request a Quote

RELATED PRODUCTS

Access Ramps

Access ramps are available with all buildings to allow for convenience when loading or unloading chemicals.

Accessories for Every Building

U.S. Chemical Storage offers a variety of chemical storage building accessories all third-party approved for your building’s compliance. From doors and shelving, to ventilation and fire supression, we have the accessories that make your storage solution perfect for your needs. View Product >RELATED ARTICLES

U.S. Chemical Storage provides two common styles of chemical storage buildings – occupancy walk-in style and non-occupancy rack style. Which one is right for you?

Chemical storage buildings require liquid-tight containment sumps to keep chemical spills from reaching the environment.

Fulton Thermal contacted US Chemical after attempting to offer packaged portable boiler storage buildings from their factory. There was a need within the industry…

YOUR PARTNER IN THE PROCESS. EXPERIENCE YOU CAN TRUST.

We deliver the precise building solution with the speed, security, and high quality that you demand.