Fast Lane Buildings: Pre-Engineered Buildings for Rapid Deployment

Fast Lane Pre-Engineered Chemical Storage Buildings

Compliance Without Compromise

Need safe, compliant chemical storage—fast? Fast-Lane Buildings are pre-engineered, PE-stamped solutions designed for speed and safety. Built to the same high standards as our custom buildings, these models ship quicker without sacrificing code compliance or quality.

With 8 ready-to-ship configurations built for real-world hazards—like flammable liquids, lithium-ion batteries, and turf chemicals—Fast-Lane Buildings offer a turnkey path to OSHA-compliant storage you can count on.

Backed by decades of expertise in hazmat storage, each model includes NC PE seals to help streamline permitting and shorten lead times—so you can stay ahead of inspections, expansions, or relocations.

Whether you’re racing to meet compliance deadlines or accommodating growth, Fast-Lane Buildings provide the reliable protection you need—fast.

Pre-Engineered Chemical Storage Buildings vs. Custom Solutions

Fast Lane Building

Pre-Engineered For Your Convenience-

◉ Ready-made with common features

-

◉ Faster PE approval (NC standard)

-

◉ Covers a Variety of Needs

-

◉ Contained Scope

-

◉ Consistent Standardization

Custom Building

Made-to-Order for Your Unique Application-

◉ Tailored to Specific Needs

-

◉ May Require Extensive Review

-

◉ Engineered for Specific Applications

-

◉ Scalability

-

◉ Limitless Options & Sizes

Which FastLane Building Is Right for You?

Non Fire-Rated Buildings for Agrichemical Applications

Compact, Compliant, and Ready for the Field

Built with agrichemicals in mind, these small-footprint Fast-Lane Buildings deliver reliable, code-compliant storage for 55-gallon drums and smaller containers. Ideal for turf management, parks and recreation, and similar operations, it meets key safety and security standards—without delay.

When placed at least 30 feet from an existing structure, these units offers safe, accessible hazardous material storage backed by FM approval and engineered to meet UL 263, ASTM E119, NFPA 30, and EPA 40 CFR requirements.

A few of the industries that may commonly use these structures are:

- Agriculture

- Turf Maintenance

- Water Treatment

- Municipalities & Public Works

- Pool Maintenance

- General Manufacturing (if placed appropriately)

Dimensions (Exterior): 10′-10″w x 8′-4″h x 8′-1″d

Drum Capacity: Twelve (12) 55-gallon drums

Approximate Weight: 3,900 lbs.

Containment Sump Capacity: 312 gallon

Dimensions (Exterior): 20′-9″w x 8′-4.25″h x 8′-4″d

Drum Capacity: Twenty-seven (27) 55-gallon drums

Approximate Weight: 6,420 lbs.

Containment Sump Capacity: 630 gallon

2-Hour Fire-Rated Lithium Battery Buildings for Emerging Risks

Compliant with current and new codes like NFPA and IFC

Compliant with current and new codes like NFPA and IFC

Built with manufacturing in mind, these small-footprint Fast-Lane Buildings deliver reliable, code-compliant storage for lithium batteries and the equipment that utilize them. Ideal for batteries in power tools, drones, power equipment for lawn, mobility, and material handling, they meet key safety and security standards—without delay.

When placed at between 10 and 30 feet from an existing structure, these units offers safe, accessible hazardous material storage backed by FM approval and engineered to meet UL 263, ASTM E119, NFPA 30, and EPA 40 CFR requirements.

A few of the industries that may commonly use these structures are:

- Manufacturing

- Apartment Complexes

- Municipalities & Public works

- Micromobility Companies

- Automotive

- Aerospace and Aircraft

Dimensions (Exterior): 11′”w x 9′-8″h x 9′ x 8″d

Containment Sump Capacity: 246 gallon

Dimensions (Exterior): 21′”w x 9′-8″h x 9′ x 8″d

Containment Sump Capacity: 549 gallon

2-Hour Fire-Rated Buildings for Palletized and Tote Storage

Efficient Footprint for Maximized Material Handling with the Utmost Safety in Mind

Built with industrial industries in mind, these two-level Fast-Lane Buildings deliver reliable, code-compliant storage for 55-gallon drums and IBC totes in a smart footprint to make material handling easy. Ideal for manufacturers and similar indusrial operations, it meets key safety and security standards—without delay.

When placed at least 30 feet from an existing structure, these units offers safe, accessible hazardous material storage backed by FM approval and engineered to meet UL 263, ASTM E119, NFPA 30, and EPA 40 CFR requirements.

A few of the industries that may commonly use these structures are:

- Food and Beverage

- Chemical

- Automotive

- Petrochemical

- Paint and Coatings

- General Manufacturing

Dimensions (Exterior): 22’w x 7′-5.5″d x 10′-9.25″h

Capacity: 8 pallets or totes

Manual Rollup Doors: 2

Containment Sump Capacity: 311 gallon

Dimensions (Exterior): 34’w x 7′-5.5″d x 12′-2.25″h

Capacity: 12 pallets or totes

Manual Rollup Doors: 3

Containment Sump Capacity: 311 gallon

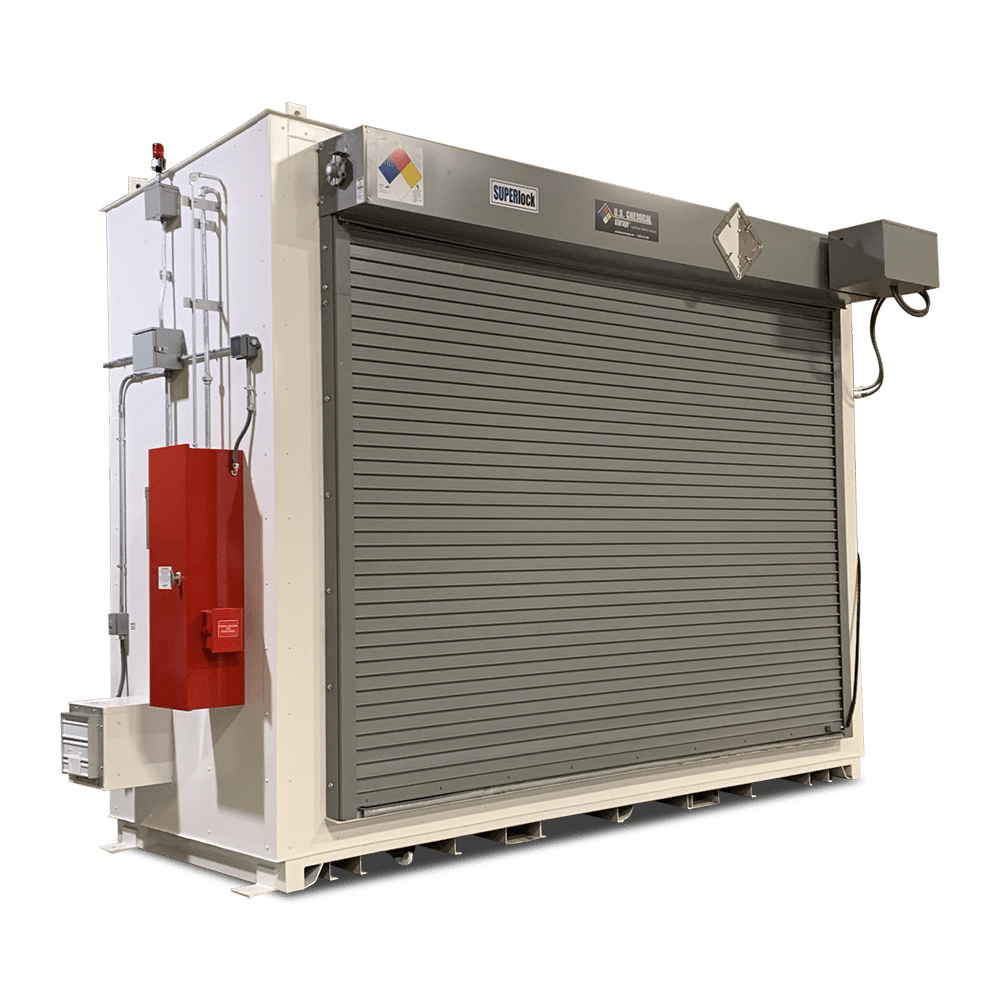

4-Hour Fire-Rated Buildings for Drum Storage and Dispensing

Sturdy, Strong, and with the Highest Level of Protection

Built for customers requiring the most stringent safety requirements, these Fast-Lane Buildings deliver reliable, code-compliant storage for 55-gallon drums with dispensing requirements. Ideal for companies that require placement within 10 feet of people, property, or even INSIDE other structures, they meets key safety and security standards—without delay.

These units offer safe, accessible hazardous material storage backed by FM approval and engineered to meet UL 263, ASTM E119, NFPA 30, and EPA 40 CFR requirements.

A few of the industries that may commonly use these structures are:

- Aerospace

- Aircraft

- Automotive

- Pharmaceutical

- Petrochemical

- Food & Beverage

Dimensions (Exterior): 11′-10″w x 8′-4″h x 9′-9″d

Drum Capacity: Sixteen (16) 55-gallon drums

Containment Sump Capacity: 236 gallon

Dimensions (Exterior): 21′-1″w x 9′-4″h x 9′-9″d

Drum Capacity: Thirty-six (36) 55-gallon drums

Containment Sump Capacity: 533 gallon

FastLane Prefabricated, Pre-Engineered Buildings

Building size is determined by the amount of hazardous material you are planning to store, the need for occupancy or inspection around these materials. We also recommend consideration of the fluxuation of raw materials in today’s economic climate and size according to possible increases of volume required in the future.

Our FastLane Pre-Engineered, Prefabricated Chemical Storage Buildings were sized according to many of the most common sizes we were creating repeatedly with our custom buildings. Each style comes in a small and mid- or large footprint to provide options and flexibility in your inventory.

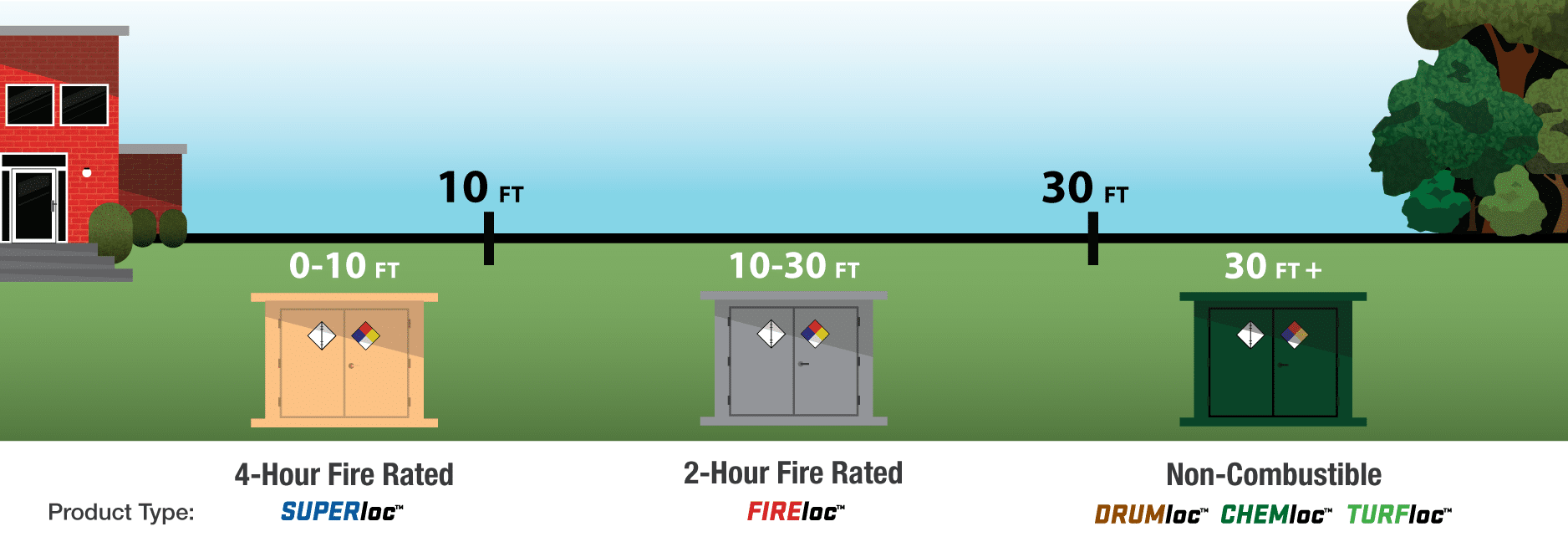

Location of the building can be either inside another building or outside to fit your needs. Fire Separation, which is the amount of fire rating required between two occupancies, or the separation distance between those two occupancies, is determined by the type of chemical or hazard being stored, and distances between buildings, egress pathways, or environmental features. This includes set backs from property lines.

To determine the proper required fire separation, it is best to consult with your local code authority (AHJ). If you are placing the building inside another building or within 10 feet of another building (which you can do with our SuperLoc construction), you’ll be required to have a 4-hour fire rating. If your hazmat storage building is located at distances 30 feet or greater your building may not be required to have a fire rating at all which can be served by a DrumLoc model.

NOTE: The AHJ should review any choice you make first, prior to ordering or placement.

Look at the general choices we provide on this page. Do you need a solution for agrochemicals? Lithium batteries? Pallet or tote storage? Dispensing and drum storage? Click through and see if these models have the features you’re looking for.

Then when you’re ready, speak to a sales associate. They can be sure that this solution is right for you.

Our experienced Technical Sales Engineers to learn about the needs of your application.

They will want to know some basic information:

1) what type of chemicals you are storing?

2) How much of it will you be storing?

3) What proximity to other buildings, people, egress paths, or environmental features will it need to be? 4) Do you require special spill containment or other options not included in these models?

Answers to these questions will dictate whether these set models will work for you, or if we need to pivot to a custom building solution.

No. These are “pre-engineered” meaning they have already been drafted and have been stamped by a Professional Engineer (PE). That is why they are available in 4-6 weeks. That is the normal time to get these “standard” buildings through our production operation.

We do have a selection of buildings that are available for Rental or Ready-To-Ship. The stock fluxuates based on availability, so be sure to check back often.

FastLane buildings are not intended to add or delete features from them – that makes you a candidate for our custom buildings at that stage. Custom engineering is also an easy process, it just is more time-consuming with back-and-forth during the design process, getting PE stamps, and lead time for any additional equipment features. A custom process usually is at 12 weeks lead time or more depending on the variables.

So while FastLane buildings aren’t on our floor ready to go, they are engineered with specific function and size in mind to serve a wide variety of industries within the amount of time it takes to get your site prepared for placement.

Absolutely! These 8 models are just the start. After 30+ years in the business, have deep experience in knowing what operations need to keep their chemical investments safe, secure, and optimized for efficiency.

You may only make a purchase of a chemical storage building once in your career. We want to make the process easy and clear from start to finish.

Features & Benefits:

Why Choose a Pre-Engineered Solution?

- Faster Path to Compliance – PE-stamped in NC and ready for permitting, reducing your wait times.

- Engineered Assurance – Designed by the same engineers as our industry-leading custom buildings.

- Industry-Specific Safety – Pre-configured models for common industries and material risks.

- Accelerated Delivery – Select models can be shipped in a fraction of standard 12+ week timelines.

- In the Time it Takes for a Concrete Pad to Cure – You can have a building delivered, ready to "plug and play."

- Premium Quality Without the Wait – With full brand reputation and regulatory confidence.

Custom Non Fire-Rated Chemical Buildings

When fire-rated construction is not necessary, U.S. Chemical Storage can still provide unparalleled protection and security for your general-purpose chemical storage needs.

Custom 2-Hour Fire-Rated Chemical Buildings

Custom engineer a 2-hour fire-rated chemical storage solution with a variety of optional explosion-proof and fire-rated safety accessories for optimal safety

Custom 4-Hour Fire-Rated Chemical Buildings

Completely customizable, SuperLoc chemical storage buildings are manufactured in bi-directional 4-hour fire rated weather-resistant construction.

Request a Quote

Fill out this form to get a quote for our product.