Chemical Storage Applications

When storing chemicals, it’s important to use the safest and most dependable chemical storage buildings available. U.S. Chemical Storage offers many different chemical storage applications for lockers, buildings, and accessories to fit your needs.

All prefabricated buildings are made from heavy-gauge metal steel construction for exceptional durability and are available with a 2-hour or 4-hour fire rating.

A Building for Every Chemical Storage Application

Available in fire-rated or non-fire-rated construction, each of our wide variety of chemical storage units and optional accessories are 100% customizable for your chemical storage applications and can be constructed to meet NFPA, FM, or Warnock Hersey standards and applicable codes. Ensure your team is fully educated and prepared to safely store your chemicals in a variety of situations when you partner with our team and find value-engineered chemical storage solutions. U.S. Chemical Storage provides solutions for these popular applications, and many more:

Hazardous Material Storage Buildings

A hazardous material (hazmat) substance can cause harm to living things or the environment. Hazmat exists in liquid, solid, or gas form and can be anything from paint to acids. All customizable hazardous material storage buildings meet EPA, OSHA, NFPA, and more. Both fire-rated and non-fire rated buildings are available.

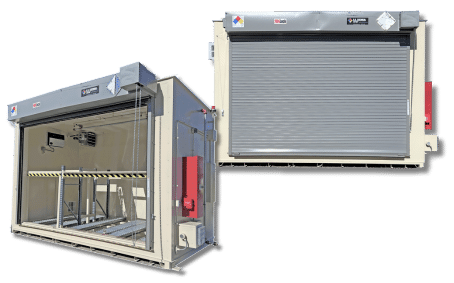

Chemical Mixing and Dispensing Storage Building

Though safely mixing and dispensing hazardous chemicals is a daily necessity for many manufacturers, the process releases hazardous fumes into the atmosphere. Separate hazardous processes from the normal working environment by using pre-engineered mixing and dispensing buildings as process isolation rooms.

Lithium Ion Battery Storage Buildings

Li-ion batteries contain lithium metal, which is highly combustible. Poor battery design, electrical shorting, overcharging, rapid discharge, or increased storage temperatures can cause li-ion batteries to overheat and ignite, posing a fire hazard. Several standard models are available, including fire-rated single-and double-room buildings with charging stations.

Pallet Mixing & Dispensing Drum Storage

Separate hazardous processes from the normal working environment by using pre-engineered mixing and dispensing buildings as process isolation rooms. Built for your specific application, buildings comply with NFPA, IFC, OSHA, and EPA safety regulations.

Request a Quote

ALL APPLICATIONS

Agricultural Chemical Storage Building

U.S. Chemical Storage engineers safe, secure storage for turf maintenance and agricultural professionals. View >Chemical Mixing and Dispensing Storage Building

Separate hazardous processes from the normal working environment by using pre-engineered mixing and dispensing buildings as process isolation rooms. View >Drum Storage

Buildings

Safely contain hazardous material drums with our DrumLoc™, ChemLoc™, FireLoc™, or SuperLoc™ drum storage buildings from U.S. Chemical Storage.

View > Hazardous Material Storage Buildings

U.S. Chemical Storage offers customizable hazardous material storage buildings that can meet EPA, NFPA, IBC, IFC codes and regulations and FM or Warnock Hersey approvals. View >Lithium Ion Battery Storage Buildings

Special storage precautions protect workers and the environment. U.S. Chemical Storage manufactures prefabricated lithium battery storage buildings designed specifically for storing li-ion batteries.

Paint Storage

Buildings

Flammable paint storage buildings offer compliant, temperature controlled, paint storage solutions while providing unmatched strength and security to your valuable paint and supplies. All prefabricated buildings are made from heavy-gauge metal steel construction for exceptional durability and are available with a 2-hour or 4-hour fire rating.

Pallet and Tote Chemical Storage Buildings

When storing and organizing palletized drums and chemical totes of non-flammable chemicals, our ChemLoc™, FireLoc™, and SuperLoc™ lines are acceptable for use as pallet and tote storage buildings. Choose from a wide range of optional accessories to increase production turnover and employee safety.

Rental Hazmat Storage Buildings

Certain projects, sites and budgets make renting a hazmat storage building the smart solution. Some projects, such as industrial renovations, construction sites, demolitions and more, may not require a permanent chemical storage solution. Other storage needs may be seasonal.

Specialized Storage

Buildings

The experts at U.S. Chemical Storage knows that some storage requirements are unique. That’s why we offer storage solutions engineered to fit your specific needs. Our specialized storage buildings are 100% customizable and provide the same attention to detail and quality manufacturing processes our company has become known for.

Flammable & Combustible Storage Solutions

Following the codes for storing flammable and combustible liquids and other hazmat is critical for keeping operations running safely and efficiently.

YOUR PARTNER IN THE PROCESS. EXPERIENCE YOU CAN TRUST.

We deliver the precise building solution with the speed, security, and high quality that you demand.