See Your Vision Come To Life with Our 3D Building Designer

U.S. Chemical Storage sets the standard of quality and compliance excellence within chemical and hazardous material storage. Now, you can create your own customized chemical storage building from top to bottom with our 3D building designer. Use our building configurator to select your construction type, size, exterior colors, flooring, accessories, speculative location placement, and more. Finished configurations will be available right within the building creator for pricing and order by contacting the U.S. Chemical Storage team or submitting your customization directly to our sales team.

Design your own metal building online free now with this following guide as you begin to explore the tool above.

How Do I Use Your Building Configurator?

First, click on “Design Your Storage Building” to start.

You’ll notice that our 3d design tool asks for different building environment factors, firstly, whether this is a commercial facility site or a military/government facility site that you’re looking to design.

Next, we have 7 segments of building your chemical storage construction:

- 1 - Business Sector

- 2 - Type of Building

- 3 - Location & Proximity

- 4 - Color (custom colors are available upon request)

- 5 - Building Sizing

- 6 - Floor Material

- 7 - Optional Accessories & Parts (more available upon request)

Click on each segment in the Design & Build tool in sequential/numerical order to select the required details of choice before the interactive tool intuitively takes you to the next segment step in the process. Along the way, you can see how your chemical storage building is shaping up by clicking and dragging around the building to rotate it. You can click between an exterior view, and an interior view.

How To Use Our Tool

Choosing Your Building Construction

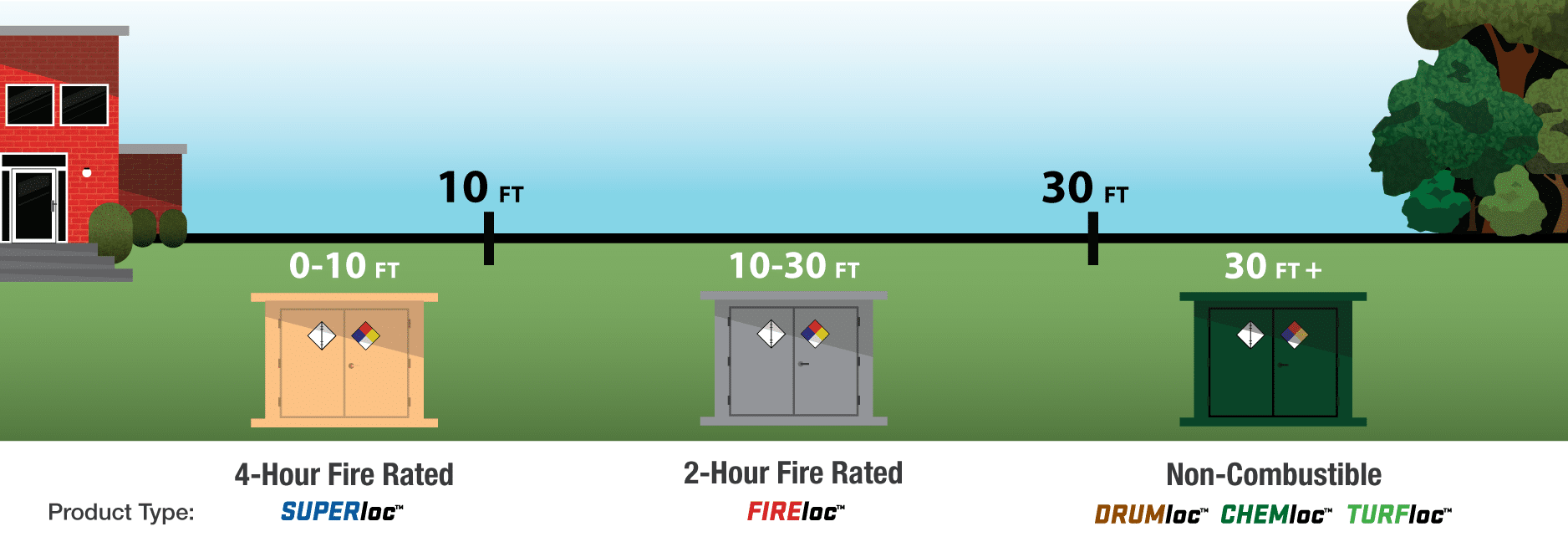

Fire rated buildings utilize fire-resistant gypsum board and are encased in completely hand welded, high-quality steel. This provides safe and compliant storage of flammable liquids and combustibles in drums, totes or other containers. These fully compliant and 100% customizable containers allow for Class 1A Flammable Chemical Storage and/or mixing of Class 1B Flammable Chemicals to occur closer to your facility. They can be built with a 2-hour rating, or a 4-hour rating. 4-hour fire rated buildings can be placed inside another building or within 10ft of another buildings (exclusions may apply).

Non fire rated buildings are often utilized if your hazmat storage building is located at distances 30 feet or greater. Your building may not be required to have a fire rating at all. In this case, gypsum board and mineral wool insulation is not utilized, but they are still constructed of steel to conform to NFPA standards.

How Do I Decide on the Construction?

First consult the Safety Data Sheet (SDS) to determine the type of chemical you’re storing and any storage requirements listed. There are two main classifications of buildings to consider: fire-rated and non-fire-rated steel buildings.

Fire separation, which is the amount of fire rating required between two occupancies, or the separation distance between those two occupancies, is determined by the type of chemical or hazard being stored, and distances between buildings, egress pathways, or environmental features. To determine the required fire separation, it is best to consult with your local code authority.

There are five main questions you should answer before engineering or design can begin on your building: what is to be stored, how much of it is being stored, and where is the location it will be stored?

- 1 - What is to be stored? (SDS sheet is important)

- 2 - How much of it is to be stored? (max/mins)

- 3 - Where will it be stored?

- 4 - Are there other needs to be addressed?

- 5 - Spill Containment Requirements?

You will also need to consult with your local “Authority Having Jurisdiction” (AHJ) or local code expert to determine your area’s specific storage building requirements. Our team at U.S. Chemical Storage has a wealth of knowledge, experience, and resources to help analyze your storage needs, but the final approval is made by the local AHJ, so you will need to ultimately ask them about your requirements early in the planning process.

It’s simple and easy to get the basics of your design visualized, and submitting the form will result in a quote and a PDF copy of their your customized 3D building design. A copy will also be sent to our sales team, and they will reach out to you within 1 business day. Then you can ask additional questions, discuss the specific hazards you face, and begin the quote process. Working with chemicals can be difficult, our goal is to make navigating their code compliant storage easy.

Need More Design Help?

Everyone works differently, so if you’d prefer an ‘off-line’ hard copy version to work through the design process, visit our “Design Guides” page and get started brainstorming with your team.

How-To Chemical Storage Building Configuration FAQs

Use of this tool was created to accommodate many users. However, it may require newer browser technology. Refer to the technical specifications below to ensure the best user experience. We recommend trying a different browser as a first course of action if the 3d tool is not working for you.

Supported web browsers recommended are: Choogle Chrome 9+, Firefox 4+, Opera 15+, Safari 15+ Microsoft Edge.

Mobile and tablet operating systems may vary. Size constraints might hinder the interactive experience.

There are some limitations to the tool. For example, the dimensions of the accessories like HVAC, fire suppression, and fans may not be proportional to the final building. It will be a broad representation of your final building. It is intended to get the conversation started so a true General Arrangement (GA) drawing can be created.

Absolutely! We can apply nearly any custom color to your building for an additional charge. We utilize Sherwin Williams paint process, so we can provide the closest color match created by one of the biggest leaders in the paint industry.

That’s okay. You don’t have to be an expert, that’s what we’re here for. Just put in the closest idea that you have, and just answer a question to move on to the next stage. When the sales engineer contacts you, they can clarify with you then.

The accessories and bolt-on parts for their build are the last essential touches for overall fire safety. The U.S. Chemical Storage technical sales engineers can help ensure greater compliance with these features. Items like explosion relief panels (ERPs), for example, are required by NFPA for some risks.

Absolutely! Visit our PARTS & ACCESSORIES page. We are adding to the offering all the time, so check back often.

Chemical Storage General FAQs

It is storage designed and manufactured specifically for housing flammable, combustible or corrosive chemicals, hazardous materials (also known as ‘hazmat’), and hazardous waste.

For more information, visit the Environmental Protection Agencies’ website at the following links:

Chemical storage buildings are designed to store hazmat in safe, segregated, and secure areas, and to prevent or contain chemical fires or explosions, or to contain chemicals from leaking out into the environment in the event of a spill. The need is largely code-driven based on the chemical or materials being stored and the proximity to people, property, or the environment. A fire code inspector, an “Authority Having Jurisdiction” (AHJ), or Insurance Inspector could be any of the people that require the use of one of our buildings and will know the code requirements in your specific location.

First consult the Safety Data Sheet (SDS) to determine the type of chemical you’re storing and any storage requirements listed. There are two main classifications of buildings to consider: fire-rated and non-fire-rated steel buildings.

There are three main questions you should answer before engineering or design can begin on your building: what is to be stored, how much of it is being stored, and where is the location it will be stored? You will also need to consult with your local “Authority Having Jurisdiction” (AHJ) or local code expert to determine your area’s specific storage building requirements.

Our team at U.S. Chemical Storage has a wealth of knowledge, experience, and resources to help analyze your storage needs, but the final approval is made by the local AHJ, so you will need to ultimately ask them about your requirements early in the planning process.

Chemical storage buildings manufactured by U.S. Chemical Storage are designed to get your operation compliant. Contact one of our technical sales engineers to learn how we can find the best solution for your compliance needs. You will also want to learn more about specific chemical storage requirements in your specific area by contacting your local “Authority Having Jurisdiction” (AHJ) who could be a local fire marshal, a municipal code official, or a city environmental department

Building size is determined by the amount of hazardous material you are planning to store, the need for occupancy or inspection around these materials, and must take into consideration the most efficient way of moving these materials into and out of your chemical storage building.

Location of the building can be either inside another building or outside to fit your needs. Fire Separation, which is the amount of fire rating required between two occupancies, or the separation distance between those two occupancies, is determined by the type of chemical or hazard being stored, and distances between buildings, egress pathways, or environmental features. To determine the required fire separation, it is best to consult with your local code authority. Inside another building or within 10 feet of another building, you’ll be required to have a 4-hour fire rating. If your hazmat storage building is located at distances 30 feet or greater your building may not be required to have a fire rating at all.

The definition of a “sump” is a pit or reservoir providing containment for spilled liquids. U.S. Chemical Storage offers leak-proof spill containment sumps in each standard model. All our sumps are tested for leaks for a 24-hour period prior to finishing. The sump is then covered by a steel or fiberglass floor grating and can even be equipped with a resistant plastic sump liner to protect against corrosive chemical accidental spills. The size of the sump is dictated by code based on the volume of liquid being stored within the building.

Start by speaking with one of our experienced Technical Sales Engineers to learn about the needs of your application. They will want to know what type of chemicals you are storing? How much of it will you be storing? What proximity to other buildings, people, egress paths, or environmental features will it need to be? Do you require special spill containment?

From there they’ll ask any related questions that determine additional options; Material Handling – Climate Control – Ventilation – Occupancy – Lights – Sensors – Alarms – Door Styles – Eyewash Stations and other requirements are not uncommon. Answers to these questions will dictate the building’s fire rating construction as well as anything else you’ll need for proper code compliance.