FREQUENTLY ASKED QUESTIONS

WE'RE HERE TO HELP!

FAQs - CHEMICAL STORAGE

First consult the Safety Data Sheet (SDS) to determine the type of chemical you’re storing and any storage requirements listed. There are two main classifications of buildings to consider: fire-rated and non-fire-rated steel buildings.

There are three main questions you should answer before engineering or design can begin on your building: what is to be stored, how much of it is being stored, and where is the location it will be stored? You will also need to consult with your local “Authority Having Jurisdiction” (AHJ) or local code expert to determine your area’s specific storage building requirements.

Our team at U.S. Chemical Storage has a wealth of knowledge, experience, and resources to help analyze your storage needs, but the final approval is made by the local AHJ, so you will need to ultimately ask them about your requirements early in the planning process.

The definition of a “sump” is a pit or reservoir providing containment for spilled liquids. U.S. Chemical Storage offers leak-proof spill containment sumps in each standard model. All our sumps are tested for leaks for a 24-hour period prior to finishing. The sump is then covered by a steel or fiberglass floor grating and can even be equipped with a resistant plastic sump liner to protect against corrosive chemical accidental spills. The size of the sump is dictated by code based on the volume of liquid being stored within the building.

Building size is determined by the amount of hazardous material you are planning to store, the need for occupancy or inspection around these materials, and must take into consideration the most efficient way of moving these materials into and out of your chemical storage building.

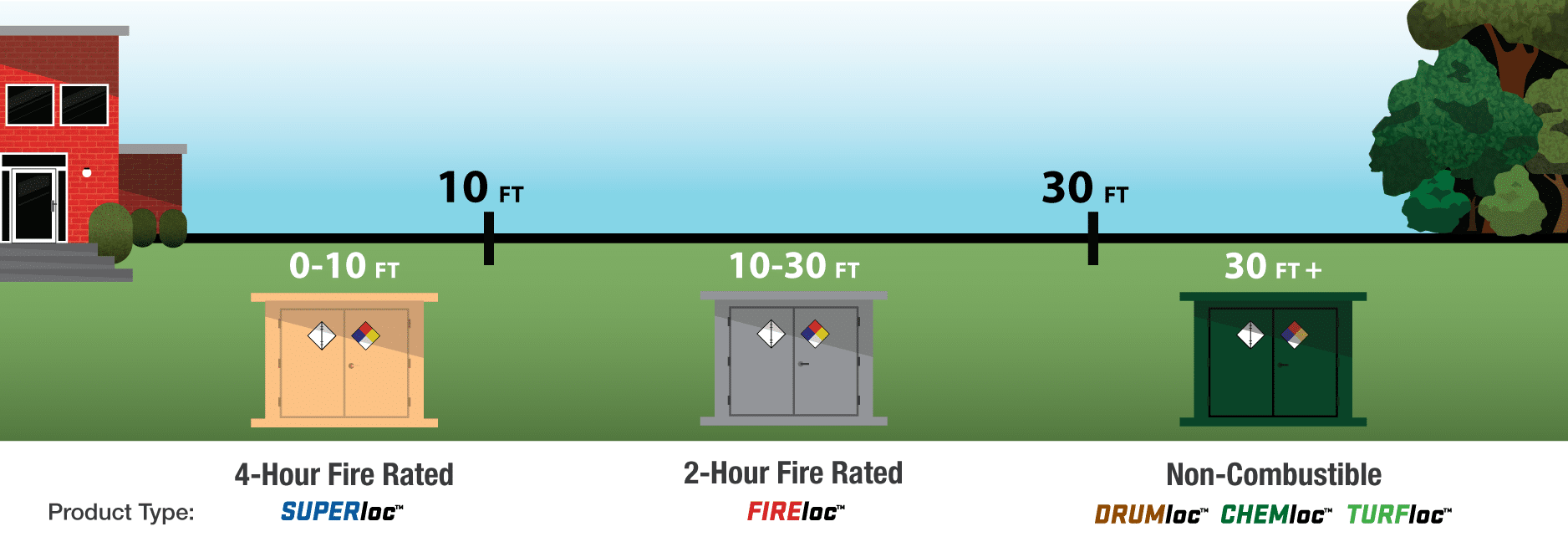

Location of the building can be either inside another building or outside to fit your needs. Fire Separation, which is the amount of fire rating required between two occupancies, or the separation distance between those two occupancies, is determined by the type of chemical or hazard being stored, and distances between buildings, egress pathways, or environmental features. To determine the required fire separation, it is best to consult with your local code authority. Inside another building or within 10 feet of another building, you’ll be required to have a 4-hour fire rating. If your hazmat storage building is located at distances 30 feet or greater your building may not be required to have a fire rating at all.

Start by speaking with one of our experienced Technical Sales Engineers to learn about the needs of your application. They will want to know what type of chemicals you are storing? How much of it will you be storing? What proximity to other buildings, people, egress paths, or environmental features will it need to be? Do you require special spill containment?

From there they’ll ask any related questions that determine additional options; Material Handling – Climate Control – Ventilation – Occupancy – Lights – Sensors – Alarms – Door Styles – Eyewash Stations and other requirements are not uncommon. Answers to these questions will dictate the building’s fire rating construction as well as anything else you’ll need for proper code compliance.

Chemical storage buildings manufactured by U.S. Chemical Storage are designed to get your operation compliant. Contact one of our technical sales engineers to learn how we can find the best solution for your compliance needs. You will also want to learn more about specific chemical storage requirements in your specific area by contacting your local “Authority Having Jurisdiction” (AHJ) who could be a local fire marshal, a municipal code official, or a city environmental department

It is storage designed and manufactured specifically for housing flammable, combustible or corrosive chemicals, hazardous materials (also known as ‘hazmat’), and hazardous waste.

For more information, visit the Environmental Protection Agencies’ website at the following links:

Chemical storage buildings are designed to store hazmat in safe, segregated, and secure areas, and to prevent or contain chemical fires or explosions, or to contain chemicals from leaking out into the environment in the event of a spill. The need is largely code-driven based on the chemical or materials being stored and the proximity to people, property, or the environment. A fire code inspector, an “Authority Having Jurisdiction” (AHJ), or Insurance Inspector could be any of the people that require the use of one of our buildings and will know the code requirements in your specific location.

First consult the Safety Data Sheet (SDS) to determine the type of chemical you’re storing and any storage requirements listed. There are two main classifications of buildings to consider: fire-rated and non-fire-rated steel buildings. There are three main questions you should answer before engineering or design can begin on your building: what is to be stored, how much of it is being stored, and where is the location it will be stored? You will also need to consult with your local “Authority Having Jurisdiction” (AHJ) or local code expert to determine your area’s specific storage building requirements. Our team at U.S. Chemical Storage has a wealth of knowledge, experience, and resources to help analyze your storage needs, but the final approval is made by the local AHJ, so you will need to ultimately ask them about your requirements early in the planning process.

FAQs - EXPLOSIVE STORAGE

For storage purposes, federal requirements classify explosive materials according to their velocity. There are three classes of explosive materials, per ATF 27 CFR 555.202:

- High Explosives – explosives which detonate by means of a blasting cap (dynamite, emulsions, flash powders, etc.)

- Low explosives – explosives which deflagrate when confined (black powder, safety fuses, ignitor cords, “display fireworks,” etc.)

- Blasting agents – explosives consisting of fuel and oxidizer, intended for blasting and unable to detonated by a No. 8 test blasting cap when unconfined (ammonium nitrate-fuel oil and certain water-gels)

For more information, visit https://www.atf.gov/explosives/explosive-storage-requirements

The ATF dictates the need for an explosive magazine. To maintain safe and reasonable practices there are rigid standards for owning explosives. Explosive storage magazines should meet standards and certifications for the proper storage of these materials. Our DynaLoc™ magazines meet and exceed these standards set forth by the U.S. government, including ATF 27 CFR, Part 555.208, and DoD 5100.

Each class requires a unique storage solution to ensure optimal safety and management. Type 2 is for storage of high explosives, Type 4 is for storage of low explosives, and Type 3 are day boxes that are used to transport both high and low explosives. Our Type 2 and Type 4 explosive storage magazines are available in both indoor and outdoor styles, and every storage type we offer features theft-resistant, weather-resistant, and fire-resistant construction.

Yes. Like all our safe storage buildings, U.S. Chemical Storage can provide custom explosive storage magazines to fit your needs. For assistance creating a custom solution for your storage needs, contact one of our experts.

It is not necessary to place your explosive storage container on a specific type of foundation. However, a foundation such as concrete can help to provide a truly level surface. Be sure to check your local guidelines to determine if any footer is required.

No. A common misconception is explosive storage magazines will contain a blast inside the unit—this is not the case. Explosive storage magazines work as a safeguard against theft and accidental detonation by improper storage and the environment.

Yes. High and low explosives that are placed in outdoor magazines should have a grounding system according to the NFPA 70 standard. Grounding protects your magazine and its contents against lightning strike, and it will need to be properly grounded by a licensed electrician. For more information, please refer to NFPA .

The term “blasting agents” refers to products used for the mining industry or the Department of Transportation’s blasting for highways. This type should utilize Type 2 indoor or Type 2 outdoor models and Type 3 day boxes during transport.

Day boxes are used for the transfer and temporary, supervised storage of your explosives. These magazines are light enough for daily transport from your overnight storage area to the job site. Our DynaLoc™ day boxes are constructed to be fire-resistant, weather-resistant, and theft-resistant.

We offer both steel and aluminum day boxes to transport explosives. If you need to repeatedly unload and load your day box and weight is a concern, an aluminum model helps reduce weight while still meeting ATF requirements. Additionally, our IME DOT dayboxes meet stringent SLP 22 requirements for “Recommendation for the Safe Transportation of Detonators in a Vehicle with Certain Other Explosive Materials.”

Yes. Our DynaLoc™ explosive storage magazine options meet or exceed federal government mandates described in ATF CFR 555—including ATF 27 CFR, Part 555.208, and DoD 5100. U.S. Chemical Storage specializes in working with government entities for unique solutions because we understand the value of mission preparedness.

FAQs - RENTALS

Building size is determined by the amount of hazardous material you are planning to store. Additionally, how you want to load and unload materials from your ready-to-ship chemical storage building is another important consideration and can help optimize your workplace efficiency. Have additional questions about how to decide on the right chemical storage building? Check our helpful guide to choosing the proper building for your chemical storage needs.

There are three main questions you should answer before engineering or design can begin on your building: what is to be stored, how much of it is being stored, and where is the location it will be stored? You will also need to consult with your local “Authority Having Jurisdiction” (AHJ) or local code expert to determine your area’s specific storage building requirements.

Our team at U.S. Chemical Storage has a wealth of knowledge, experience, and resources to help analyze your storage needs, but the final approval is made by the local AHJ, so you will need to ultimately ask them about your requirements early in the planning process.

Depending on our available stock, we can offer refurbished ready-to-ship chemical storage buildings. To inquire about used inventory, please contact a sales engineer.

Yes. We offer rental buildings, generally for a minimum contract of six months, with options for both short- and long-term renewable contracts.

However, these buildings are also available for purchase outright, which can fill your requirement immediately. Our stock of ready-to-ship chemical storage buildings rotates periodically. You can browse our current ready-to-ship inventory any time online or by contacting a sales engineer to discuss your options.

Having options like these are vital if your supply chain needs to suddenly adjust, if you expand into a new space, or for temporary hazardous material storage while a custom building is being manufactured for you.

Chemical storage buildings manufactured by U.S. Chemical Storage are designed to ensure your operation is compliant.

We offer many C1D2 FM-approved units as well as C1D1 models with explosive panels. All our buildings are EPA, OSHA and NFPA compliant. All secondary containment sumps are properly sized for regulations and leak tested prior to shipping.

For help finding the best solution for your chemical storage needs, contact one of our sales engineers. For questions regarding local building codes, please contact your local authority.

Our ready-to-ship chemical storage buildings are suitable for storing chemicals according to National Electric Code® standards. Proper storage of is determined by what chemicals you are storing, how much of the chemical you are storing, and the proximity of the storage building in proximity to people or property. For help determining which building is right for you, contact one of our chemical storage experts.

FAQs - LITHIUM

Lithium-ion batteries are known to spontaneously ignite and pose fire hazards due to overheating from poor battery design, damage to the battery through a drop or strike, electrical shorting, overcharging, rapid discharge, or increased storage temperatures. Li-ion batteries contain lithium metal, which is highly combustible.

- Extremely high temperature fire easily achieving over 1,000° F in minutes

- Violent explosions that can cause injury and quick fire spread

- Toxic gas release full of metals and carcinogens

- Thick black smoke the quickly obstructs vision

- Re-ignition after extinguished hours, days, or even weeks after initial event

While codes and regulations are still struggling to catch up to the dangers of lithium-ion batteries, U.S. Chemical Storage has been making hazmat buildings for this purpose for nearly a decade. Several designs of buildings to store or charge lithium batteries are available. Most are 2-hour or 4-hour fire-rated.

Many customers choose between single and multi-room buildings to separate storage from charging stations, assembly rooms, or testing areas. They often have multiple options for fire suppression, and sumps to contain the runoff of heavy metals and toxins.

Li-ion battery storage buildings from U.S. Chemical Storage are custom-engineered to fit your quantity and arrangement needs. We also provide large-scale lithium-ion battery storage for bigger needs.</br?

Depending on our available stock, we can offer refurbished ready-to-ship chemical storage buildings. To inquire about used inventory, please contact a sales engineer.

- Power outlets

- Fire suppression systems

- Firehose hookups for fire department water deluge

- LED lights

- Sensors & alarms

- Workbenches (for buildings with charging rooms)

- Temperature & climate controls

- Multi-tiered shelving or cubbies

- Fiberglass flooring

- Rubber matting

- Extra deep sumps

- Chemical resistant paint

Additional options and safety accessories are available. As with any U.S. Chemical Storage product, our lithium-ion battery storage buildings have an industry-leading 15-year structural warranty.

Need a larger than standard footprint? Modular configurations are also available possible for all lithium-ion storage buildings.

Absolutely. We can and we do.

Military bases cannot afford injuries and the loss of mission-critical equipment. Comms, robots, drones, vehicles, and more are utilizing the ease of rechargeable lithium batteries to make missions safer for our troops.

Let us share what we know for the fire and life safety of this increasingly crucial source of power.

Built upon a design created to meet or exceed ATF 27 CFR, Part 555.208 for the temporary storage and transport of high explosives, the DynaLocLTC Safety Case for lithium battery storage and transport has been modified with important features specifically for lithium battery risks.

With little code and regulation guidance for new battery transport and storage as well as proper isolation or transport of DDR or suspected damaged batteries, increased fire protection and suppression measures like those in the DynaLocLTC can protect your people and your property from catastrophic events.

Visit the LTC page for more information.

Request a Quote

SuperLoc™ Flammable Storage Buildings

4-hour flammable storage buildings ensure compliance while improving efficiency and allow for flammable storage located within 10 feet from and even inside your facility.

How to Avoid Paint Fires & Quality Incidents in Manufacturing

Find out how flammable paint storage buildings help mitigate risks when handling and storing industrial paint products.

Accessories for

Every Building

Choosing the right chemical storage building accessories to include in your building will ensure safe, compliant storage of your hazardous materials.

Modular

Buildings

You aren’t limited to a building solution that will only fit on a truck. We can engineer buildings that can be prefabricated, then reassembled on site in 2, 5, 7 or more pieces.